Latest Innovations in Ply Machinery: Enhancing Efficiency and Precision

Plywood manufacturing has come a long way with the integration of advanced machinery designed to improve efficiency, reduce waste, and ensure precision. Today, we delve into some of the latest innovations in ply machinery, including Glue Mixers, Glue Spreaders, Pedal Choppers, D.D. Saws, Ripsaws, Belt Sanders, and Seasoning Chambers, which are reshaping the woodworking industry.

1. Glue Mixer

The Glue Mixer is an essential component in plywood manufacturing, ensuring a uniform blend of adhesives for consistent bonding. Modern glue mixers now feature:

- Automated Controls: Allowing precise mixing ratios for different glue types.

- High-Speed Mixing: Reducing preparation time.

- Energy Efficiency: Using less power while maintaining performance.

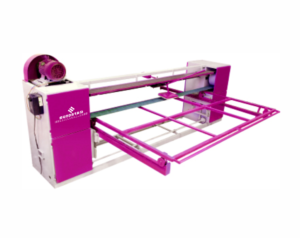

2. Glue Spreader

Glue Spreaders have seen significant upgrades to enhance application accuracy. Features include:

- Adjustable Rollers: For uniform glue application across varying plywood thicknesses.

- Non-Stick Coating: Preventing glue buildup and ensuring smooth operation.

- Integrated Cleaning Systems: Minimizing downtime between glue changes.

3. Pedal Chopper

Pedal Choppers are used for cutting excess material and shaping plywood edges. The latest models boast:

- Ergonomic Designs: Reducing operator fatigue.

- Precision Cutting Blades: Delivering clean and accurate cuts.

- Safety Enhancements: Including emergency stops and protective guards.

4. D.D. Saw (Double Dimension Saw)

D.D. Saws are pivotal for accurate cutting and dimensioning of plywood sheets. Modern versions include:

- CNC Integration: Enabling automated cutting with programmable dimensions.

- Dust Extraction Systems: Keeping the workspace clean and safe.

- High-Speed Motors: Improving throughput without compromising precision.

5. Ripsaw

Ripsaws are indispensable for cutting plywood along the grain. Innovations in this machinery feature:

- Laser Guides: For pinpoint accuracy.

- Variable Speed Control: Adapting to different materials and cutting requirements.

- Robust Construction: Ensuring durability and reduced vibrations.

6. Belt Sander

Belt Sanders are essential for surface finishing, and the latest models include:

- Adjustable Speed Settings: Catering to different sanding needs.

- Vacuum Attachments: Reducing dust and improving air quality.

- Heavy-Duty Belts: Offering longer service life and better performance.

7. Seasoning Chamber

Seasoning Chambers are critical for drying and conditioning plywood to the desired moisture content. Modern chambers are equipped with:

- Smart Sensors: Monitoring and controlling temperature and humidity.

- Energy-Efficient Designs: Reducing operational costs.

- Customizable Settings: Tailored to specific wood types and thicknesses.