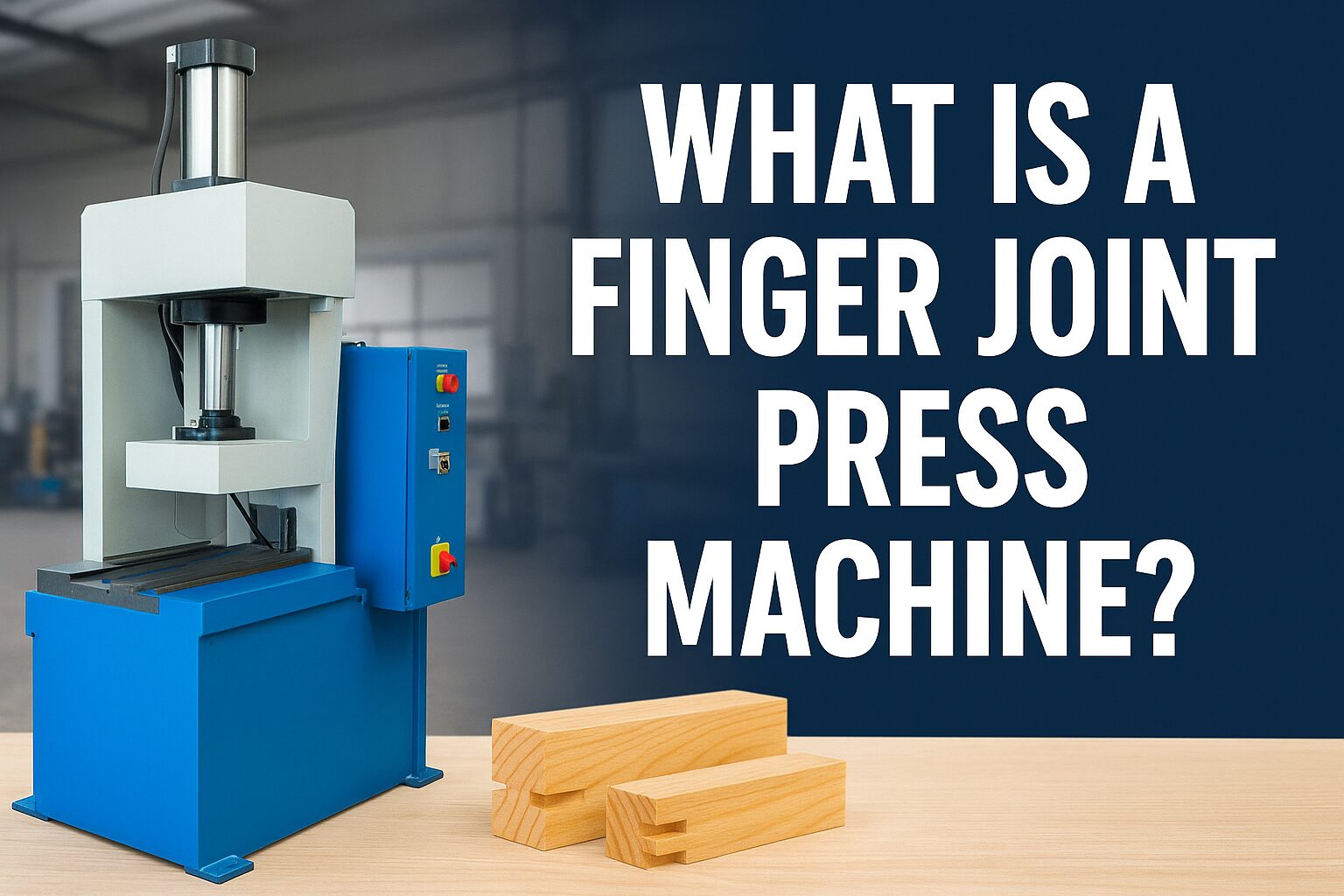

What Is a Finger Joint Press Machine? Working, Features & Uses – Complete Guide by Sundaram Corporation

The woodworking and timber industry has evolved significantly over the years, and modern manufacturing demands stronger, longer, and more efficient wooden components. One of the most remarkable innovations that supports this growing need is the Finger Joint Press Machine. This machine not only enhances wood strength but also helps industries reduce waste and improve productivity.

At Sundaram Corporation, we specialize in providing high-performance finger joint press machines designed to deliver precision, durability, and maximum output for woodworking units. This blog explains everything you need to know about what a finger joint press machine is, how it works, its key features, and where it is used.

- What Is a Finger Joint Press Machine?

A Finger Joint Press Machine is a specialized woodworking machine used to join short pieces of wood to create longer, stronger, and more stable wooden boards. The joint formed resembles interlocking “fingers,” which is how it gets its name.

These interlocking fingers provide:

- Higher strength than regular butt joints

- Greater load distribution

- Minimal material wastage

- Excellent bonding for long timber production

The machine is widely used in furniture manufacturing, panel production, joinery applications, and timber processing industries.

- How Does a Finger Joint Press Machine Work?

The working of a finger joint press machine involves multiple stages, each designed for precision wood joining. Here’s a simplified breakdown of the process:

Step 1: Wood Preparation

Wooden blocks or small timber pieces are prepared by trimming and aligning them to the required size. The ends must be flat and clean before processing.

Step 2: Finger Cutting (Profile Creation)

The ends of the wooden pieces are cut into finger-like profiles using a finger joint cutter.

These are usually:

- V-shaped

- Zig-zag shaped

- Interlocking rectangular cuts

This profile is essential for a strong joint.

Step 3: Glue Application

A high-quality wood adhesive is applied precisely to the finger profiles. Proper glue application ensures:

- Maximum bonding strength

- Long-lasting joints

- Resistance to stress and tension

Step 4: Pressing & Jointing

The wood pieces are placed inside the Finger Joint Press Machine, where powerful hydraulic or pneumatic pressure pushes them together. The interlocking fingers lock firmly, creating a seamless and strong connection.

Step 5: Curing & Finishing

Once pressed, the joint requires a short curing time. After drying:

- The board becomes ready for cutting

- Surface finishing can be done

- Panels can be further processed for furniture or construction

- Key Features of a Finger Joint Press Machine

A modern finger joint press machine, like those offered by Sundaram Corporation, comes with advanced features that enhance performance and efficiency:

✔ High-Precision Finger Cutting Mechanism

Accurate finger profiles ensure tight joints and superior bonding strength.

✔ Heavy-Duty Hydraulic Press

Strong and reliable hydraulic pressure creates perfect joints with uniform compression.

✔ Automatic Feeding System (optional)

Automation helps increase production speed while reducing human effort and error.

✔ Strong Build Quality

Machines are built with high-grade steel and rigid frames for long-term operation.

✔ Efficient Glue Application System

Ensures consistent glue distribution for durable joints.

✔ Safety Controls & Emergency Stop System

Prevents accidents and ensures safe operation.

✔ Easy Maintenance & Accessibility

Designed for quick cleaning, tool changes, and servicing.

- Uses of a Finger Joint Press Machine

Finger joint press machines are used across a wide range of industries due to their ability to enhance timber strength and reduce wood waste.

Major Uses Include:

- Furniture Manufacturing

Used for making:

- Table tops

- Chair legs

- Cabinet frames

- Bed components

- Plywood & Panel Industry

Essential for producing long and stable wooden boards.

- Construction Timber

Used for structural wooden beams, frames, and long boards.

- Modular Kitchen & Interior Industry

Creates strong and aesthetic wooden parts used in cabinets, shutters, and wall panels.

- Door & Window Frame Production

Ideal for making long-lasting wooden frames with high strength.

- Flooring Industry

Finger-jointed material offers excellent stability and durability for wooden flooring.

- Joinery & Carpentry Workshops

Perfect for small and medium-scale woodworkers who want to maximize material usage.

- Benefits of Using a Finger Joint Press Machine

Industries prefer finger joint machines because they offer:

✔ Stronger joints than traditional wood joining methods

✔ Reduced wood wastage & increased material utilization

✔ Cost-effective production for long wooden boards

✔ Improved dimensional stability

✔ High-quality finish suitable for premium furniture

✔ Faster manufacturing with automation options

Why Choose Sundaram Corporation?

Sundaram Corporation is a trusted name in woodworking machinery, offering:

- High-precision finger joint press machines

- Robust and long-lasting build quality

- User-friendly designs

- Competitive pricing

- Reliable after-sales support

- Custom-built machine options

Our machines are designed to deliver efficiency, accuracy, and maximum productivity for all types of woodworking industries.